Leading supplier of high-end and specialised equipment to the oil and gas industries in sub-Saharan Africa, Energas Technologies, is launching the FAB Valve Series, a flame arrester/breather valve combination. The FAB valve provides a cost-effective, high-performance solution with minimal maintenance for use in the majority of tank storage applications.

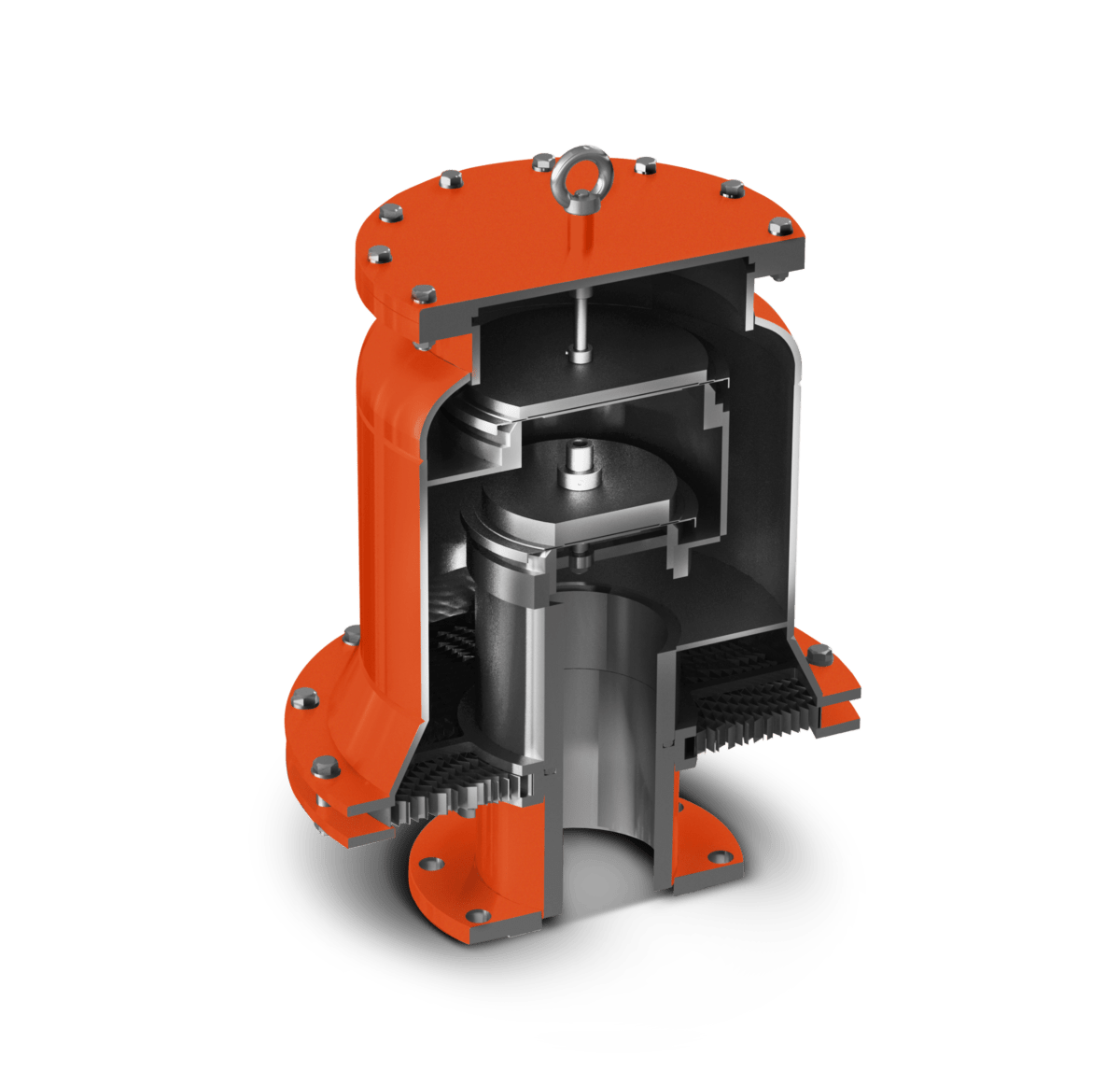

Manufactured by Elmac Technologies, the flame arrester and breather valve (FAB Valve) combination functions as a combined end-of-line pressure-vacuum vent and a deflagration arrester, explains Energas Product Manager, Laetitia Jansen van Vuuren.

The pressure relief valve prevents vapour losses up to the specified set-pressure and ensures reliable protection against excessive vacuums. The flame arrester element further protects the equipment against atmospheric deflagration. The FAB valve is generally stipulated by EPA and API regulations in venting applications.

The FAB valve incorporates enhanced crimped ribbon technology in the flame arrester element. The channel dimensions of the flame arrester element are optimised for deflagration protection while ensuring minimal maintenance requirements and maximum flow performance. In the event of external ignition, the flame arrester prevents flame transmission from entering the piping systems and tanks containing flammable fluids. The unique operating model of the FAB valve allows self-draining of the flame arrester element. This allows visual inspection and ensures minimal clogging of the element under normal operating conditions.

Elmac Technologies’ FAB valves are available with carbon steel and stainless steel as standard housing materials, but other special materials are also available on request. The standard maximum operating temperature of FAB valve is 60°C (FAB-DN series), however, with FAB-E series the higher operating temperatures of up to 150°C are possible. The flame arrester element provides optimum flow performance and minimal pressure drop with compact design, lightweight and easy to install. The unique valve design provides complete weather protection.

The sizes range from 2” to 12” flanges with all internationally recognised connection standards (ANSI, DIN, among others). The set-pressure can be up to 3,5 kPa and the vacuum can be up to 2 kPa. The FAB valve series is ATEX certified for gases in Explosion group llA1, llA, llB1, llB2 and llB3. It is type tested to EN ISO 16852 standard and approved according to the ATEX Directive 2014/34/EU.